The unique range of Ventomat air valves have been sold in Australia since 1997 and installed by major authorities and councils in Sydney, Melbourne, Perth, Canberra, Brisbane, Adelaide, Northern Territory, Hobart and most areas in between.

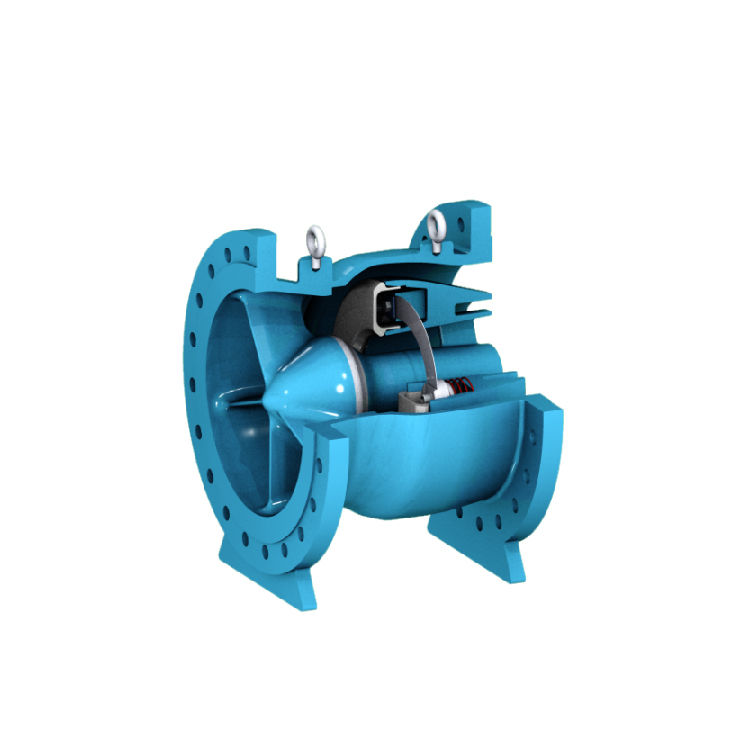

NCV - Ventomat Nozzle Check ValveThe world leader in Air Valves Technology

Vent-O-Mat Advantages & Key Features

Available Configurations |

|